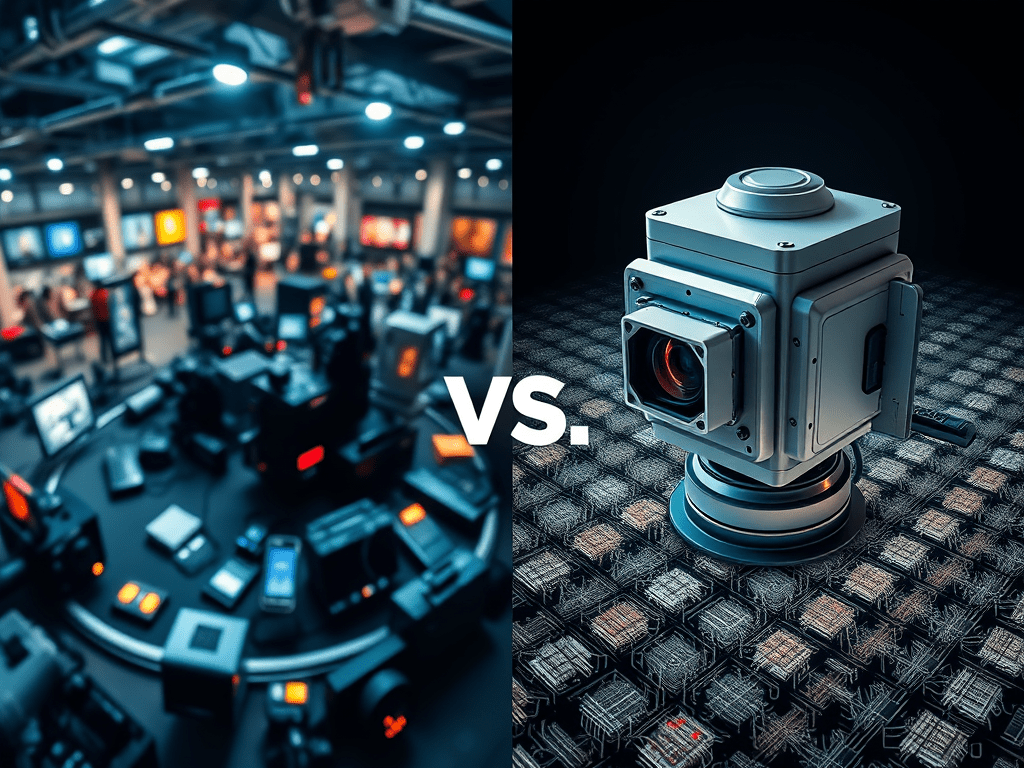

360° Imaging vs LiDAR Scanning in Engineering Projects

In engineering, accurate site representation is essential for design validation, progress monitoring, and lifecycle management. Two technologies dominate this space: 360-degree imaging and LiDAR (Light Detection and Ranging) scanning. While both capture spatial context, they differ fundamentally in data type, accuracy, cost, and integration potential. This article provides a dense technical comparison for engineers and decision-makers evaluating these solutions.

1. Data Capture Methodology

- 360° Imaging

- Uses cameras (dual fisheye lenses or multi-lens rigs).

- Produces RGB raster images mapped onto a sphere (equirectangular projection).

- Captures visual context but not depth data.

- LiDAR Scanning

- Uses laser pulses to measure distance.

- Produces 3D point clouds with millimeter-level precision.

- Captures geometric detail but lacks color without additional RGB overlay.

2. Accuracy and Precision

- 360° Imaging:

- Limited geometric precision; suitable for qualitative analysis.

- Errors occur due to parallax and stitching artifacts.

- Accuracy ~ few centimeters at best (when combined with photogrammetry).

- LiDAR Scanning:

- Sub-centimeter accuracy in terrestrial laser scanners (TLS).

- Can detect structural deviations, alignments, and tolerances.

- Standard in surveying and structural analysis.

3. File Formats and Data Structures

- 360° Imaging:

- JPEG/PNG (equirectangular), HDRI for lighting, EXIF metadata for geolocation.

- Lightweight, easy to share, but limited analytical depth.

- LiDAR Scanning:

- LAS/LAZ (standard for point clouds), E57, PLY.

- Heavy datasets (gigabytes per scan), require specialized software (Autodesk ReCap, Bentley Pointools, CloudCompare).

4. Integration with Engineering Workflows

- 360° Imaging:

- Linked to BIM models as reference for visual verification.

- Easily embedded in SharePoint, Teams, or GIS dashboards.

- Suitable for training, progress photos, remote inspections.

- LiDAR Scanning:

- Imported into CAD/BIM platforms for as-built modeling and clash detection.

- Essential for reverse engineering, deformation analysis, and precision surveying.

- Increasingly used in digital twin environments with IoT overlays.

5. Hardware and Cost Considerations

- 360° Imaging:

- Cameras: $400 – $2,000 (consumer/prosumer range).

- Capture speed: seconds per location.

- Minimal storage requirements (~10 MB per photo).

- LiDAR Scanning:

- Terrestrial LiDAR scanners: $20,000 – $100,000+.

- Capture speed: minutes per scan, multiple setups needed.

- Storage-intensive (~10–50 GB per site).

6. Market Use Cases

- 360° Imaging:

- Progress monitoring in construction.

- Remote inspections in oil & gas.

- Visual records for compliance audits.

- LiDAR Scanning:

- Structural analysis of bridges, tunnels, industrial plants.

- Survey-grade mapping of terrain and urban infrastructure.

- As-built modeling for retrofit or renovation projects.

7. Convergence and Hybrid Approaches

The engineering industry increasingly adopts hybrid workflows:

- Capture LiDAR scans for high-precision geometry.

- Overlay 360° images for visual context.

- Result: A georeferenced digital twin with both accuracy and realism.

Software like Autodesk Recap, Trimble RealWorks, and Bentley ContextCapture support these fusion models.

Summary Table

| Criterion | 360° Imaging | LiDAR Scanning |

|---|---|---|

| Data Type | RGB raster, spherical projection | 3D point cloud (XYZ coordinates) |

| Accuracy | Low (cm-level at best with photogrammetry) | High (mm-level precision) |

| File Formats | JPEG, PNG, HDRI, EXIF | LAS/LAZ, E57, PLY |

| Hardware Cost | $400 – $2,000 | $20,000 – $100,000+ |

| Storage Needs | Low (~10 MB/image) | High (10–50 GB/site) |

| Capture Speed | Seconds | Minutes per scan |

| Integration | BIM (visual verification), GIS, collaboration | CAD/BIM (as-built modeling, clash detection, survey) |

| Use Cases | Inspections, training, progress monitoring | Structural analysis, surveying, digital twins |

For further technical background: